Implemented isolation design between transmission and mold

NEWTOP-1250C is a highly stable and intelligent food paper box forming machine

Implemented isolation design between transmission and mold

NEWTOP-1250C is a highly stable and intelligent food paper box forming machine

Automatic spray oil lubrication, longitudinal axis transmission and gear structure

This model adopts a tabletop fixed mold for easy cleaning and maintenance, ensuring quality and hygiene. PLC integrated photoelectric tracking and servo feed, suitable for the production of 25-90 oz paper bowls, with a speed of 120pcs/min, can make paper cups, paper bowls, ice cream cups, and barbecue boxes.

.png)

.png)

.png)

|

Model |

NEWTOP-1250C |

|

Weight |

3500kg |

|

Machine encasement dimension |

3100 x 1600 x 2350mm |

|

Cup counter encasement dimension |

1230 x 720 x 1900mm |

|

Rated power |

Three-phase, 380V, 31KW |

|

Compressed air |

0.6-0.8MPa, 0.6 m3 /min |

|

Max Capacity |

120pcs/min |

|

Paper materials |

Single PE / double PE / PLA |

|

Paper thickness |

0.2825-0.445mm |

|

Product range |

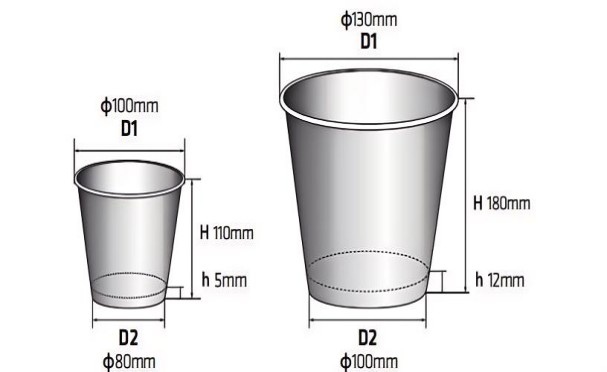

(D1)φ100-130mm (H)110-180mm (D2)φ80-100mm (h)5-12mm |

| Grease Lubrication |  |

Hand Movement11 |

| Ultrasonic |  |

Ultrasonic |

| Hot Air Generator |  |

Bottom |

| Hot Air Generator |  |

Broadside |

| Paper Cup Lubrication |  |

Cup bottomlubr ication |

| Airborne detection |  |

Collect table |

| Piping |  |

Single line pipeline |