New Debao people pursue the concept of high quality and technology leading.

By changing the working mode with intelligent paper cup machine to make the operation more and more simple.

In the continuous expansion of the milk tea consumption market, the rise of large-sized paper cups has become an important trend that cannot be ignored. As consumers' demand for "large capacity" and "multiple ingredients" grows increasingly strong, the sales of large-sized milk tea cups with specifications of 20oz and above have shown significant growth, especially occupying a core position in the "large cup" and "extra-large cup" options of chain brands. For example, some domestic brands even use 22oz as a characteristic specification to meet consumers' pursuit of rich taste and quantity.

Currently, the popular large-sized milk tea cups in the market start with 20oz as the basic standard, deriving various specifications adapted to different scenarios.

1. 20oz (approximately 590ml-600ml)

As the basic mainstream size in the large cup market, 20oz has become the first choice of some brands due to its feature of "moderate capacity without waste".

2. 22oz (approximately 650ml-680ml)

This size focuses more on the needs of "those who love multiple ingredients" and has a high penetration rate in composite milk tea categories.

* Heytea: The "extra-large cup" specification is convenient for adding large chunks of ingredients such as mango pieces and grapefruit granules. The cup body is thick, so it is not easy to soften even when filled with iced drinks.

* Naixue's Tea: The 22oz cup type is used for milk tea series. The curved design of the cup body fits the arc of the palm, making it suitable for long-time carrying in takeaway scenarios.

* Mixue Bingcheng's "extra-large cup" specification is suitable for adding extra pearls, coconut jelly and other ingredients. The double wall cup design prevents the cup body from deforming due to excessive ingredients.

Due to their special height and large capacity, large cups often appear in the form of double wall cups.

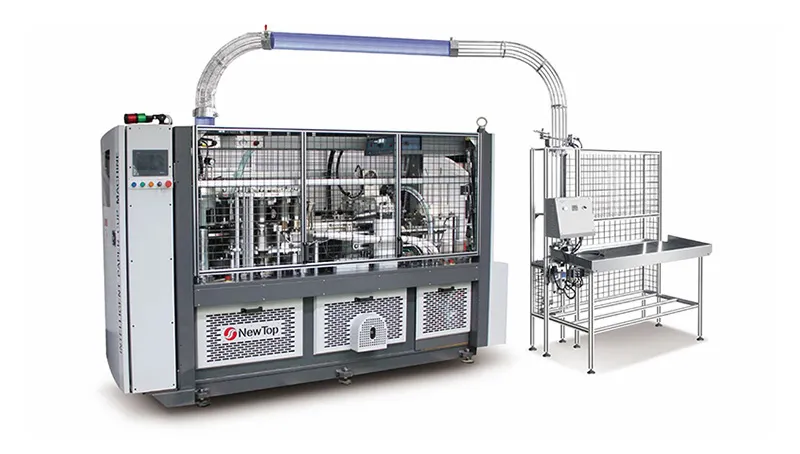

(Note: NEWTOP-118C is suitable for producing 5-16oz paper cups)

To produce double wall large cups with both heat insulation and leak-proof properties, the combined set of NEWTOP-118C Automatic Paper Cup Machine and NEWTOP-118CDT can be adopted. This set of equipment uses dual processes of ultrasonic welding and side heating to form a tight sealing structure on the side of the cup body. The bottom is heated by three hot air streams to make the bottom bonding more uniform, completely solving the problem of side leakage of large cups. The bottom adopts three hot air heating technologies to make the cup bottom bonding more uniform, perfectly overcoming the problem of bottom leakage of large-capacity cups. The refined craftsmanship of NEWTOP-118CDT ensures that the outer sticker and inner cup fit precisely, forming a double heat insulation protective cover, which fully meets the market's quality expectations for large cups. The combined equipment operates at a maximum speed of 120pcs/min. While ensuring efficiency, the produced paper cups have both heat insulation and leak-proof properties, providing consumers with a safe and comfortable holding experience, and are deeply favored by quality-focused chain brands.

When enterprises decide on Paper Cup Machine brands and production sizes, they need to establish market adaptability elasticity. The iterative speed of consumer demand requires equipment to have flexible production conversion capabilities. When brands launch combined specifications of 20oz and 22oz, the modular design of NEWTOP models can be compatible with the full-size production of large-capacity milk tea cups, requiring only the replacement of molds of different sizes. There is no need to purchase additional main machines, which significantly reduces the transformation cost.

More technical parameters and production schemes for large-sized paper cups are continuously updated. If you need a customized large cup production scheme, please feel free to contact the Newtop business team—we will combine your production capacity needs, cost budget and brand positioning to provide a full-process solution from equipment selection to process optimization, helping you seize the opportunities in the large cup market.

2.5oz-12oz Paper Cup Size

175 pcs/min Max Capacity

5oz-16oz Paper Cup Size

150 pcs/min Max Capacity

2.5oz-10oz Paper Cup Size

158 pcs/min Max Capacity