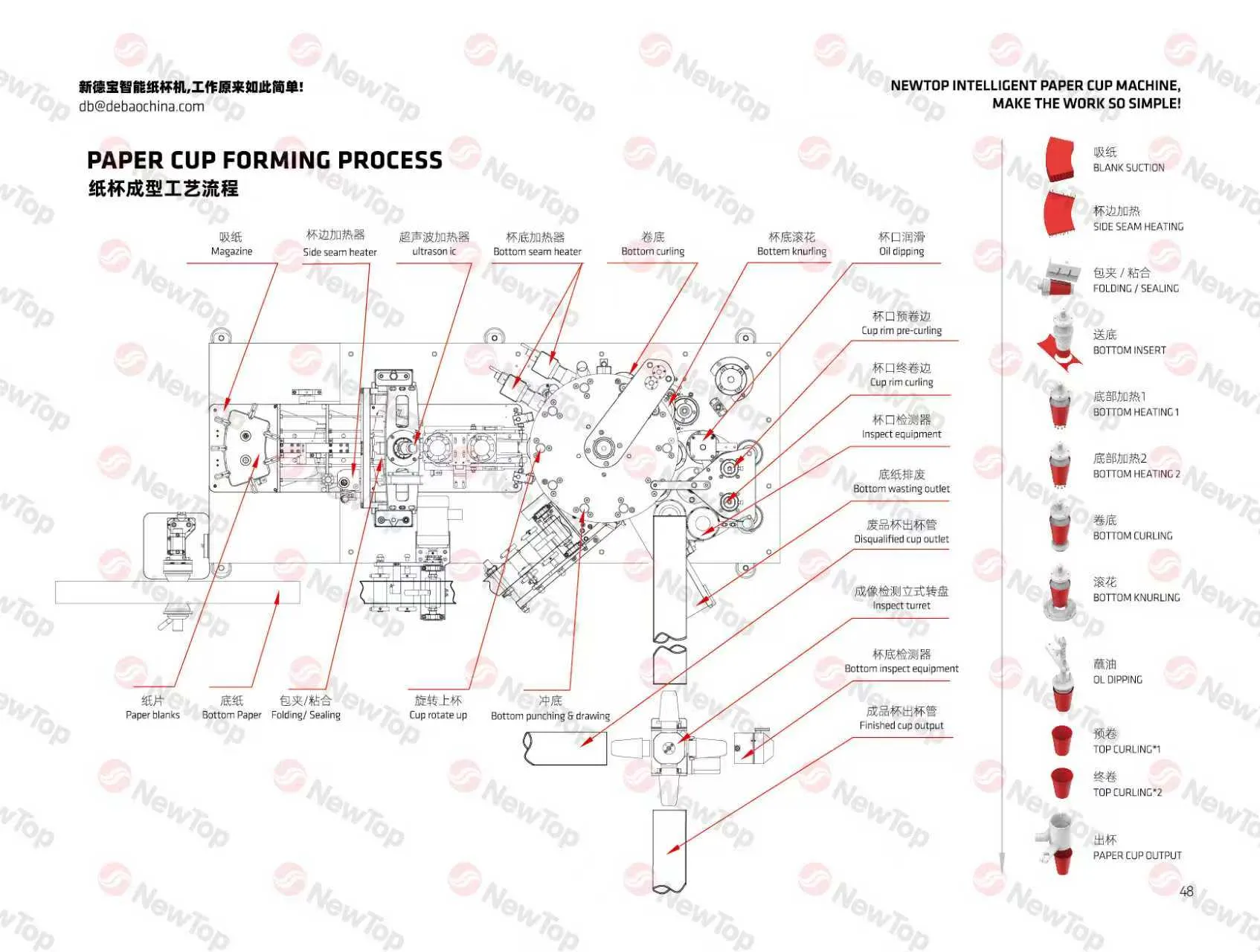

1. NEWTOP-1250S Paper Bowl machine is suit for 12-45OZ of cold / hot bowls. The maximum speed can reach 120pcs/min.

2. Implemented isolation design between transmission and mold.

3. Mechanical parts are guaranteed for 5 years, electrical parts and vulnerable parts are guaranteed for 1 year.