New Debao people pursue the concept of high quality and technology leading.

By changing the working mode with intelligent paper cup machine to make the operation more and more simple.

In Southeast Asia, an enterprise newly venturing into paper cup production was struggling to break into the local market. With a thriving coffee culture in the region, there is a strong demand for double wall heat-insulating paper cups. However, lacking industry experience, the enterprise had no idea which type of machine to choose and was worried about being unable to achieve stable production after putting the equipment into operation. Upon recommendation from peers, they contacted NewTop comany.

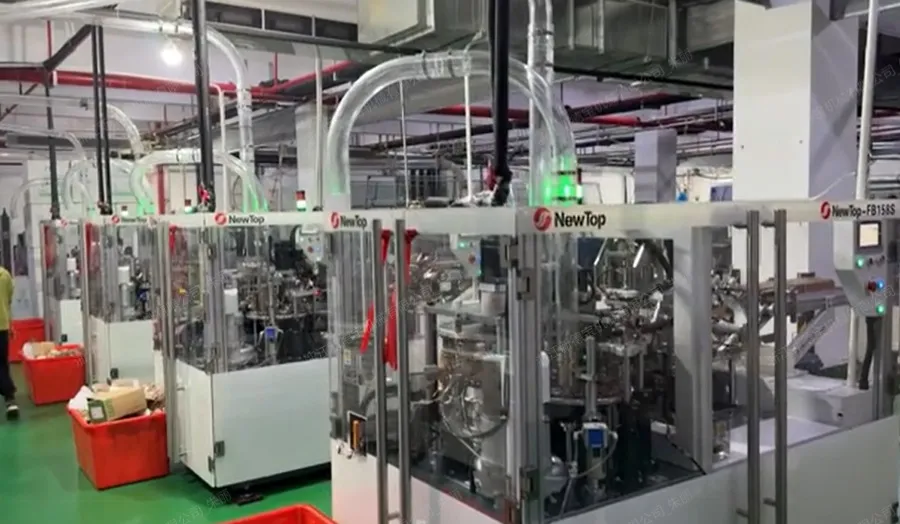

The salesman of NewTop comany learned that the mainstream demand in the client's local market was for 12oz double wall coffee cups. Based on this market demand, we recommended the NEWTOP-FB158S + NEWTOP-118DT paper cup machine online solution. After placing the order, the client's biggest concern was equipment installation and subsequent operation. After all, the engineers in their factory were all novices who had never even touched basic paper cup machine operations. Upon learning this, NewTop immediately arranged for an engineer with years of debugging experience to provide on-site service. Considering that the client's factory was located in a remote industrial area, the engineer set off two days in advance, carrying a full set of special tools and spare parts.

Upon arrival at the site, the NewTop engineer completed the installation of the 4 interconnected machines in no time. During the actual installation process, he gave the client's team a detailed explanation of the core structure and operating principles of the equipment. In the machine debugging phase, the NewTop engineer operated the equipment personally, calibrating each parameter according to the client's paper materials and requirements, and let the client's engineering team observe the entire process. Then, he guided the client's engineers to operate the equipment step by step, from starting the equipment, monitoring production data to handling simple faults. In just one month, the client's team not only could operate the equipment independently but also mastered daily maintenance and common fault handling skills.

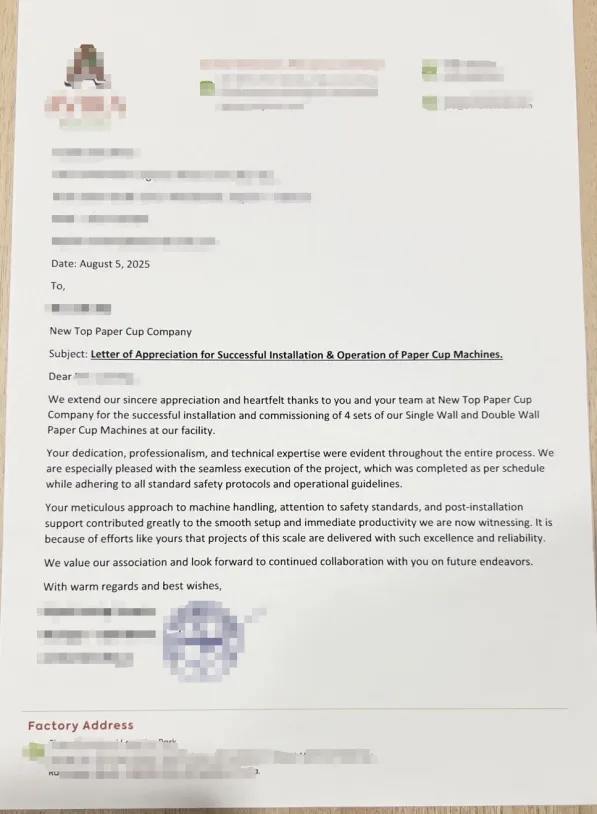

Later, the client specially sent a thank-you letter, which read: "Throughout the process, your dedication, professionalism, and technical expertise were fully demonstrated. We are particularly satisfied with the smooth execution of the project, which was completed as scheduled and in compliance with all standard safety regulations and operating guidelines. Your meticulous machine operation, emphasis on safety standards, and post-installation support have contributed significantly to the smooth installation and rapid production we are witnessing now. It is thanks to your efforts that a project of this scale could be delivered so excellently and reliably."

For NewTop, serving every client well is never just about helping them buy suitable machines. We are more eager to stand in the client's shoes, accompanying them throughout the journey with professionalism and patience - from scheme planning when they are new to the industry, to improving details during production, and to timely responses to unexpected situations. We are committed to not only helping clients establish scientific and efficient production schemes but also safeguarding every step of their production journey with high-quality after-sales service.

11oz-43oz Paper Bowl Size

180 pcs/min Max Capacity

8oz-22oz Paper Cup Size

260pcs/min Maximum capacity

2.5oz-12oz Paper Cup Size

175 pcs/min Max Capacity