New Debao people pursue the concept of high quality and technology leading.

By changing the working mode with intelligent paper cup machine to make the operation more and more simple.

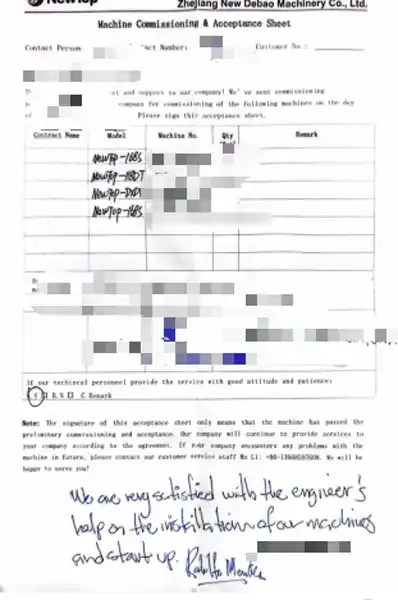

Total number of machines: 4sets of machines: 2 set of NEWTOP-168S; 1 sets of NEWTOP-DXD110;1 set of NEWTOP-118DT

In recent years, coffee culture in South America has been steadily rising, with the number of local coffee shops increasing year by year. Coupled with the steady expansion of the fast food industry, this has driven a surge in demand for takeout beverage packaging. A client deeply engaged in Argentina's paper container sector is planning to focus on the supply chain for branded coffee shops and urgently needs stable and efficient paper cup production equipment. After searching for “stable paper cup machines” on Google, the client found detailed product information on the New Debao Machinery Co., Ltd. website and left their contact details. New Debao promptly arranged for a professional sales manager to reach out to them.

After in-depth communication with the client, the sales manager clarified the client’s core needs—supplying high-quality coffee cups for branded coffee shops with extremely high demands for equipment stability, production efficiency, and product precision. Based on these needs, the sales manager recommended the NEWTOP-168S high-speed intelligent paper cup machine (which has since been upgraded to NEWTOP-168S9). This model offers flexible configuration, strong paper adaptability, and stable production speed of 168 pcs/min, making it suitable for the production of high-gram-weight, high-end brand cold/hot paper cups ranging from 5-16oz.

Considering the client's focus on coffee cups, which require corrugated outer sleeves, the sales manager also recommended a matching paper cup outer sleeve machine. During further communication to confirm details, it was learned that the client’s factory had limited workers, and manual packaging was not only inefficient but also increased costs and hygiene risks. The sales manager once again provided optimization advice, recommending the NEWTOP-DXD110 automatic packaging machine, which can automatically count, bag, and seal paper cups, greatly reducing the reliance on manual labor while improving packaging efficiency and hygiene standards, aligning with the client's cost-reduction and efficiency goals.

Ultimately, the client placed a bulk order, which included 2 NEWTOP-168S high-speed intelligent paper cup machines, 1 NEWTOP-118DT machine, and 1 NEWTOP-DXD110 packaging machine.

Once the machines arrived at the client’s factory, our commissioning engineers immediately went to the site to provide installation and debugging services. From parameter calibration and circuit debugging to operational testing, the entire process was carried out with professionalism, efficiency, and meticulous attention to detail, ensuring the production line quickly reached optimal operating conditions. This timely and thoughtful professional service not only earned the client's high recognition and satisfaction but also received a written commendation.

As an international industry leader in the field of intelligent food packaging paper container equipment, New Debao's clients are spread across the globe. It is the preferred brand for many international brand paper container suppliers. To fully support the normal production of client factories worldwide, Zhejiang New Debao Machinery Co., Ltd. uses the "Five Bodies, One Position" intelligent paper cup machine marketing model as its core, regularly dispatching professional technical engineers to provide timely and efficient on-site services, solving customer problems. In the future, New Debao will continue to accompany global clients on their steady journey forward with top-tier products, comprehensive services, and leading technology, writing a new chapter of win-win collaboration.

11oz-43oz Paper Bowl Size

180 pcs/min Max Capacity

8oz-22oz Paper Cup Size

260pcs/min Maximum capacity

2.5oz-12oz Paper Cup Size

175 pcs/min Max Capacity