New Debao people pursue the concept of high quality and technology leading.

By changing the working mode with intelligent paper cup machine to make the operation more and more simple.

In fact, a high-quality machine is not determined by a single function, but by a perfect combination of a series of precise technical specifications.Think of it as the machine’s DNA—its core blueprint that determines output, reliability, and your final profit. From the molding precision and heating system efficiency to the production speed and automation level, each spec is a critical piece of the puzzle. As someone who’s walked countless factory floors, I can tell you that overlooking even one detail is the difference between a smooth-running asset and a costly, temperamental piece of metal. Let’s cut through the noise and build your ultimate specification checklist.

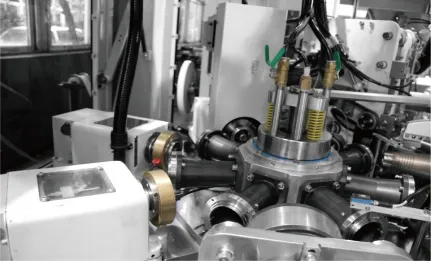

Let’s start where the action is: the mechanical guts. When you’re investing in a paper bowl making machine, you’re buying physical engineering. The frame isn’t just a frame; it’s the skeleton. I’ve seen machines with lightweight frames shudder under high-speed operation, leading to misalignment and a headache of maintenance issues. A quality machine, like those engineered by NewDebao, uses heavy-gauge, reinforced steel. This isn’t just for show—it ensures vibrational stability, which directly translates to consistent bowl forming and longer life for every moving part.

Next, examine the molding station. This is where your paperboard transforms. The specifications for the forming dies—their material, coating, and temperature control—are non-negotiable. Are they made from high-chromium alloy steel? Are they hardened and precision-polished to a mirror finish? This detail dictates the final bowl quality, ease of product release, and how often you’ll need to stop for cleaning. A poorly finished die will cause paper to stick, creating rips and increasing waste—a silent profit killer.

Finally, consider the drive system. Is it a traditional mechanical drive or a modern servo-driven system? Here’s my take from the field: while robust mechanical systems are proven, the precision and energy efficiency of servo motor systems are revolutionizing the industry. They allow for finer control over the forming process, reduce jerky movements that can wrinkle paper, and can cut energy use by up to 20-30% according to the European Paper Packaging Association. This spec isn’t just about power; it’s about control and cost.

.webp)

Heat is the magic that makes paper pliable. But in production, it’s a science that must be exact. The thermoforming system in your paper cup and bowl machine is its energy heart. The first spec to scrutinize is the heating method. Older or cheaper machines often use direct resistance heating, which can be uneven and harsh on the paper’s coating. Superior machines employ indirect oil heating or advanced far-infrared systems. Why does this matter? Indirect oil heating, for instance, provides a stable, uniform temperature gradient across the entire forming mold. This prevents scorching or under-heating, ensuring every bowl has a consistent, smooth wall without weak spots.

Look closely at the temperature control specification. It should be digital, PID-controlled, and zone-specific. A single temperature reading for the whole unit is a red flag. A proper hot pressing system will have independent controls for the side wall heater and the bottom heater. This allows an operator to fine-tune the process for different paper grammages or coatings. In one visit to a midsize converter, I saw them reduce their scrap rate by 7% simply by switching to a machine with zoned temperature control, because they could perfectly adapt to a new batch of paperboard without trial and error.

The thermal efficiency rating is a spec often buried in the manual, but ask for it. It tells you how much of the energy drawn is actually used for forming versus lost to the environment. A well-insulated, efficiently designed heating system doesn’t just save on electricity bills; it creates a more stable working environment for the machine and the operators around it.

This is where machines separate themselves. You can have the strongest mechanical system, but without intelligent control, it’s just a brute. The control system is the brain of your automatic paper bowl making machine. The minimum today is a programmable logic controller (PLC) with a user-friendly touchscreen Human-Machine Interface (HMI). But the spec sheet should go deeper.

What’s the level of programmable automation? Can you store recipes for different bowl sizes—like 8oz, 12oz, 16oz—and switch between them with one tap? This changeover time is critical. A machine that takes 90 minutes to manually re-tool is losing you money. Advanced machines, and this is where NewDebao shines with its NDB-Series, boast “one-touch changeover” where servo motors auto-adjust most settings, slashing changeover to 15-20 minutes.

Also, examine diagnostic capabilities. A quality control system won’t just flash an “Error E05.” It will tell the operator “Bottom Heater Zone 3 Temperature Sensor Fault” directly on the screen. This predictive maintenance insight is invaluable. I recall a plant manager telling me this feature alone saved them from a 36-hour production halt, as they caught a failing sensor during a routine check before it caused a major breakdown.

Integration is key. Does the control system have the capability to connect with downstream equipment, like a stacking and packaging unit, or even factory ERP systems? This isn’t futuristic thinking; it’s about building a scalable, data-driven production line today.

Everyone looks at the big number: production speed. It’s usually advertised as “60-80 pieces per minute (PPM).” But here’s the industry secret you need to know: the sustainable, real-world output is what counts. A machine might peak at 80 PPM for 10 minutes, but due to heating stability or paper feed issues, it might average only 55 PPM over an 8-hour shift. Always ask for the documented average operational speed.

The relationship between speed and stability is inverse. Pushing a machine to its absolute maximum often increases the reject rate. The key spec to find is the optimal speed range—the sweet spot where the machine runs smoothly with a reject rate below, say, 1.5%. A reputable manufacturer will provide this data. For a standard 12oz bowl, a high-quality machine should comfortably and consistently run in the 50-70 PPM range with high stability.

Also, calculate the output capacity in context. A speed of 70 PPM translates to 4,200 bowls per hour. But does that include the time for automatic roll splicing? What about planned maintenance windows? When NewDebao consultants work with clients, they build a realistic production model that factors in all these variables, not just the theoretical max. This helps you match the machine’s true capacity to your market demand, avoiding both under-investment and over-capacity.

The main unit gets all the attention, but the supporting cast makes the show run. The paper feeding system is a prime example. Is it a simple unwind stand, or does it include a precision tension controller and an automatic splicing unit? An automatic splicer allows a new paper roll to be glued to the expiring one without stopping the machine. This one feature can boost your effective production time by 5-8% per day—a massive gain over a year.

Then comes the bottom punching and sealing unit. The precision of the bottom punch and the application of the food-grade glue are microscopic in scale but monumental in effect. The spec should state the glue application method: wheel, nozzle, or extrusion. Nozzle application, often controlled by the same servo system, is typically more precise and uses less adhesive, reducing both cost and the risk of leakage.

This is where customized paper bowl machine solutions enter the conversation. Your raw material might be unique—perhaps you’re using a particular recycled board or a special PLA waterproof coating. A quality manufacturer doesn’t sell you an off-the-shelf box; they adapt. Can the feeding mechanism handle your paper’s specific thickness (caliper) and tensile strength? Can the heating system be tuned for your coating’s melting point? NewDebao, for instance, often runs sample materials in their test center to calibrate machine settings before delivery, ensuring a plug-and-play experience for the buyer. This tailored approach turns a generic machine into your machine.

A machine’s quality is also measured by how gracefully it ages. Ease of maintenance is a spec you must visualize. Are grease points easily accessible? Are commonly replaced parts, like sealing rings or heating elements, modular and easy to swap out? I’ve advocated for machines where critical components can be replaced in under 30 minutes by a trained technician, minimizing downtime.

The service and support structure behind the brand is part of the technical specification sheet. What is the standard warranty? Does it include on-site installation and training? What is the guaranteed response time for technical support? A manufacturer with a global network of trained engineers, like NewDebao maintains, provides a safety net that is priceless. Ask for their Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) statistics for critical components. These numbers reveal their confidence in the machine’s reliability and their own logistical efficiency.

Finally, consider the operational training provided. The best machine in clumsy hands will underperform. Comprehensive, hands-on training that covers operation, routine maintenance, and basic troubleshooting is not an add-on; it’s a core part of the technical package that ensures you hit your productivity targets from day one.

Choosing the right Paper Bowl Machine is a technical deep dive, but it’s also a strategic business decision. It’s about matching a detailed set of engineering specifications—from the molding precision and servo control to the thermoforming stability and after-sales support—to your specific production reality and growth ambitions. Don’t just buy a machine; invest in a production system designed for longevity and return.

Ready to translate these specifications into a tangible solution for your factory? Contact NewDebao’s engineering team today for a personalized consultation and a live demonstration. Explore our range of high-precision, customizable paper bowl making machines designed to meet your exact output and quality goals. Visit our product page [www.newdebao.com/contact-us] to start the conversation.

2.5oz-12oz Paper Cup Size

175 pcs/min Max Capacity

5oz-16oz Paper Cup Size

150 pcs/min Max Capacity

2.5oz-10oz Paper Cup Size

158 pcs/min Max Capacity