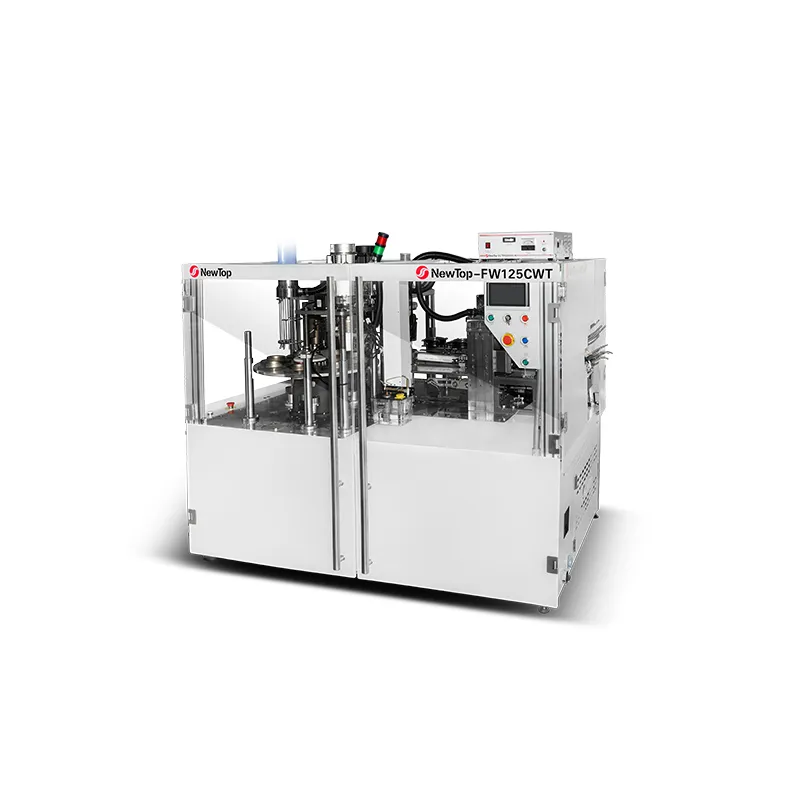

1. NEWTOP-FW125CWT Servo-driven paper cup sleeve machine is suit for 16-42OZ bowl jacket forming which is widely used in ripple cups etc. The maximum speed can reach 160pcs/min.

2. Dual-turntable process and full servo drive architecture for intelligent, versatile and efficient production.

3. Mechanical parts are guaranteed for 3 years, electrical parts and vulnerable parts are guaranteed for 1 year.