New Debao people pursue the concept of high quality and technology leading.

By changing the working mode with intelligent paper cup machine to make the operation more and more simple.

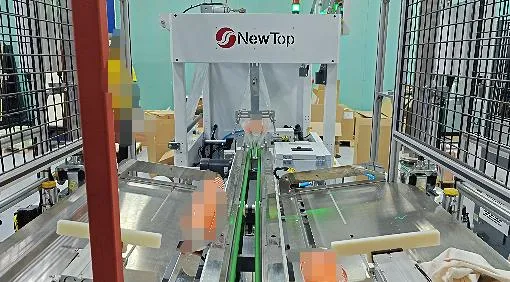

Total number of machines: 12 sets

5 sets of NEWTOP-138S Customizable Paper Glass Machine

5 sets of NEWTOP-118DT Double Wall Paper Cup Machine

2 sets of NEWTOP-DXD110 High Speed Intelligent Paper Cup Packing Machine

The COVID-19 pandemic reshaped the disposable tableware market:

1. Consumers prioritized hygiene and safety, with "avoiding shared items" becoming a consensus.

2. Demand for disposable paper cups surged, especially in catering takeout, due to their "use-and-throw" nature.

3. This market shift made the South American customer’s collaboration with New Debao a classic case of counter-trend growth.

· At the start of the pandemic, the customer searched for "smart paper cup production line" online and found New Debao Company.

· Customer’s pain points:

Original equipment had limited capacity and relied on manual packaging.

Could not meet surging orders or hygiene standards (reducing interpersonal contact).

· Decision to cooperate: After comparing parameters and sanitary designs, the customer ordered 2 NEWTOP-138S Customizable Paper Glass Machine, attracted by their fully enclosed system and 150 cups/minute stable capacity.

The anti-scalding double-layer cups produced by NEWTOP-138S met "safe and contactless" requirements, becoming designated supplies for local chain coffee shops.

Equipment ran without failures, with daily capacity stably exceeding 100,000 pieces—far beyond expectations.

As orders continued to rise, the customer added 8 more machines after 2 weeks:

① 5 NEWTOP-138S + 5 NEWTOP-118DT Double Wall Paper Cup Machine formed an intelligent production line for different-spec double-layer cups.

② 2 NEWTOP-DXD110 Automatic Paper Cup Packing Machines were added as core "epidemic prevention" equipment:

* Enabled fully automated production (from forming to bagging/sealing) with fewer workers.

* Addressed "labor shortage" and "gathering risk" challenges during the pandemic.

During the busiest quarter, the production line ran continuously with NewTop equipment:

* Double-layer cups’ insulation and aseptic standards won high-end orders (chain restaurants, hospital logistics).

* Customer feedback: "Each NewTop machine boosted confidence in handling urgent orders. Expanding from 2 to 10 units increased capacity and order security via intelligent automation."

This special-period cooperation highlighted NewTop equipment’s strength in extreme markets:

Stable performance withstood order peaks.

"Low-contact, high-cleanliness" design built a hygienic safety line for customers, turning every order into trust.

11oz-43oz Paper Bowl Size

180 pcs/min Max Capacity

8oz-22oz Paper Cup Size

260pcs/min Maximum capacity

2.5oz-12oz Paper Cup Size

175 pcs/min Max Capacity